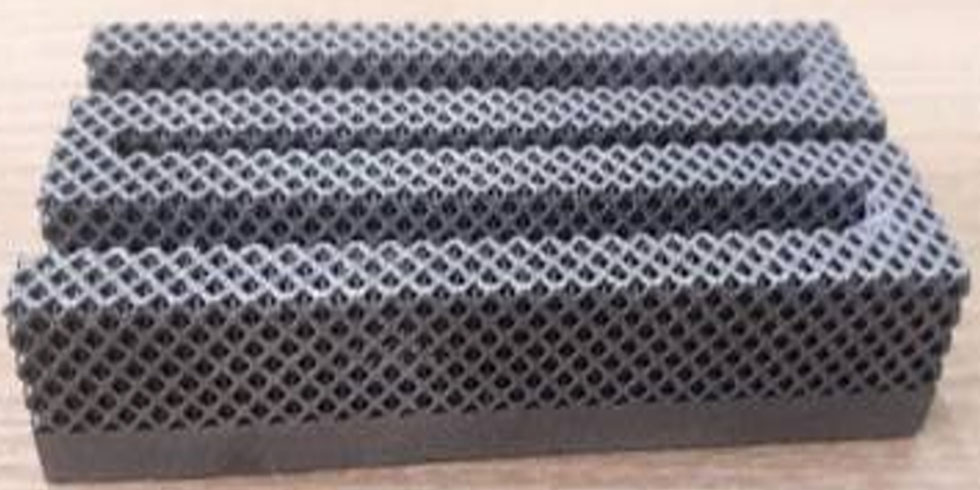

Indian scientists have created a multipurpose heat sink that uses 3D printing to drain heat from mechanical devices at a 50% faster pace than traditional sinks.

Existing heat exchange and heat sink techniques use distinct units to fulfil different purposes. Multiple functions have been combined in a single unit in the new technology. Heat pipes, vapour chambers, heat exchangers, and noise-reducing heat sinks can all be made using it.

Dr Shankar Krishnan, Associate Professor Department of Mechanical Engineering, IIT Bombay, developed the technology enabled by 3D printing in combination with electroplating to withstand load while dissipating heat with support from the Department of Science and Technology, Government of India under the 'Make in India' initiative. He has also filed a national patent on 'noise-reducing heat sinks,' which will be followed by the international patent. Validation has been done both experimentally and computationally.

The technology is light and can withstand mechanical stress, dissipate heat, and absorb sound. It can be utilised in the electronics, electronics, and power/cooling industries.

According to the open-literature study, there is currently no such product on the market. Electronics thermal management is a ten-billion-dollar business that could benefit from this technology. This advancement is also beneficial to any fan-mounted heat exchanger. Although cost is a risk, it can be mitigated by working with high-volume producers.

Prof. Krishnan is in talks with a major semiconductor manufacturer or high-volume manufacturing to enable compact noise (both broadband and tonal) reducing heat sinks, and the technology is in the third phase of Technology readiness levels (verification with experimental to verify that the concept operates as planned).

Add Comment