Digital printing’s introduction sparked colossal change and an industry makeover, but it’s a drop in the big blue ocean compared to what’s on the horizon. Digital graphics printing, functional printing, and 3D structural printing are the future of printing, covering everything from smart packaging to on-demand manufacturing, and the benefits will be felt widely across our society.

We will continue seeing rapid advancements in digital color printing in graphic communications, including new types of inks and toners that can create higher image quality and specialized effects. But there is another large new growth opportunity beyond document printing that will come from the ability to digitally print on a wider range of materials. Technology will soon be able to deliver all the benefits of digital with the image quality and run-cost of analog printing on longer runs and films to plastics and metals. By 2025 we will see inline digital presses in distribution centers and plants, and also specialized printers and kiosks in retail stores that will offer on-demand personalized printing on products.

Next in line to graphics printing is functional printing. By 2025 we will see a much more mature printed and hybrid electronics ecosystem, with software that will simplify electronics design, and digital manufacturing systems that will produce a variety of sensors, circuits, memory, communications, and power options on flexible, low cost smart tags or print them directly on products and packaging. Functional printing will give us the ability to extend intelligence pervasively to documents, products, and packages helping to make the Internet of Things real. This will enhance existing services, from cold chain logistics to environmental monitoring.

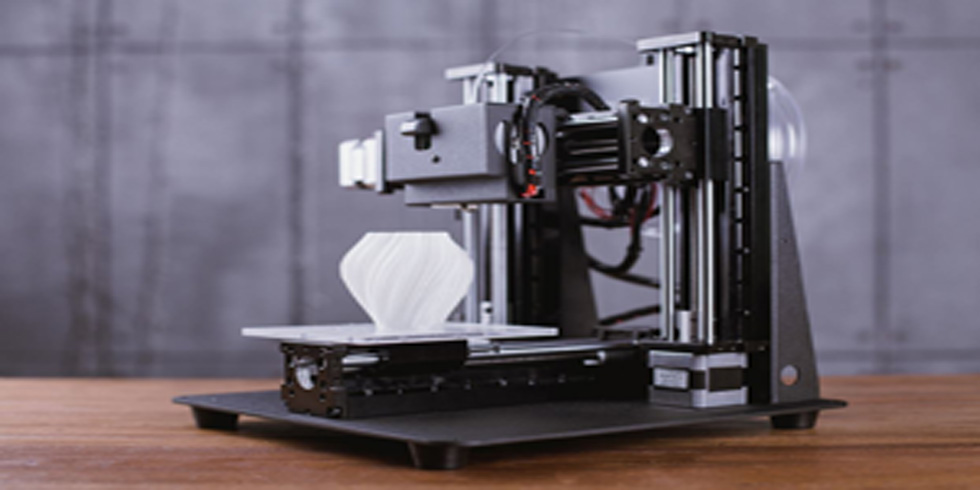

3D printing of parts or structural printing is mostly limited to rapid prototyping or specialized low-volume production based on cost and speed limitations of 3D printing processes and materials. Over the next several years, new advances in high-speed 3D printing of plastics and even 3D metal printing will enable large-volume production of complex parts, with enough strength and at low enough cost to compete with traditional manufacturing processes.

While the growth of 3D printing in India is currently restricted by low investments, limited R&D facilities & manufacturing units; 3D printing market is set to grow by $13.6 billion by 2022 owing to electronics and automotive sector. The combination of structural 3D printing and digital functional printing will enable creation of personalized smart products, not just parts, on demand. This value proposition is especially compelling in the consumer health and fitness industry. We are already seeing early products of smart clothing with embedded sensors and feedback. In time to come the industry will witness personalized applications combining structural and functional properties.

Different types of new printing technologies will drive big changes across the print industry. Print providers will be faced with new opportunities that are too good to miss, evolving to offer a one-stop-shop for customers and potentially providing everything from initial designs to finished products to analytics and recommendations. The latest printing innovations will also work alongside smarter software to make the market more accessible over time.

Smarter design software using Artificial Intelligence will help guide non-expert designers and operators to use these new technologies, and cloud-based software will make it easier to collect data, perform analytics, and close the loop on marketing communications and new IoT applications.

Add Comment